It’s All On Your Head

RealWear has taken the industrial world by storm with their assisted reality device: the RealWear® Head-Mounted Tablet (HMT). Unlike extended reality goggles or glasses, the RealWear HMT provides a display that is out of users’ way, allowing them to execute critical operational and maintenance procedures while having the ability to access crucial information hands-free: by using voice commands.

As an official RealWear partner, JourneyApps provides modular, pre-built functionalities that, when combined with RealWear, provides a new avenue for industrial companies to achieve operational excellence.

This post explores the possibilities of this combination of technologies in the area of Standard Operating Procedures.

An SOP By Any Other Name

Standard Operating Procedure (SOPs) and Standard Maintenance Procedures (SMPs) are sets of detailed instructions documenting how to perform specific operational or maintenance tasks. Depending on how safety knowledge is managed within a specific company, these procedures could also be called work instructions, quality procedures, quality work instructions or something different.

For this post we’ll be using the term “SOP” to refer to any set of instructions detailing how to perform a given task to a certain standard, the purpose of which is to ensure the health and safety of employees, ensure equipment reliability and provide a basis for accident investigation.

What To Understand About SOP Lifecycles

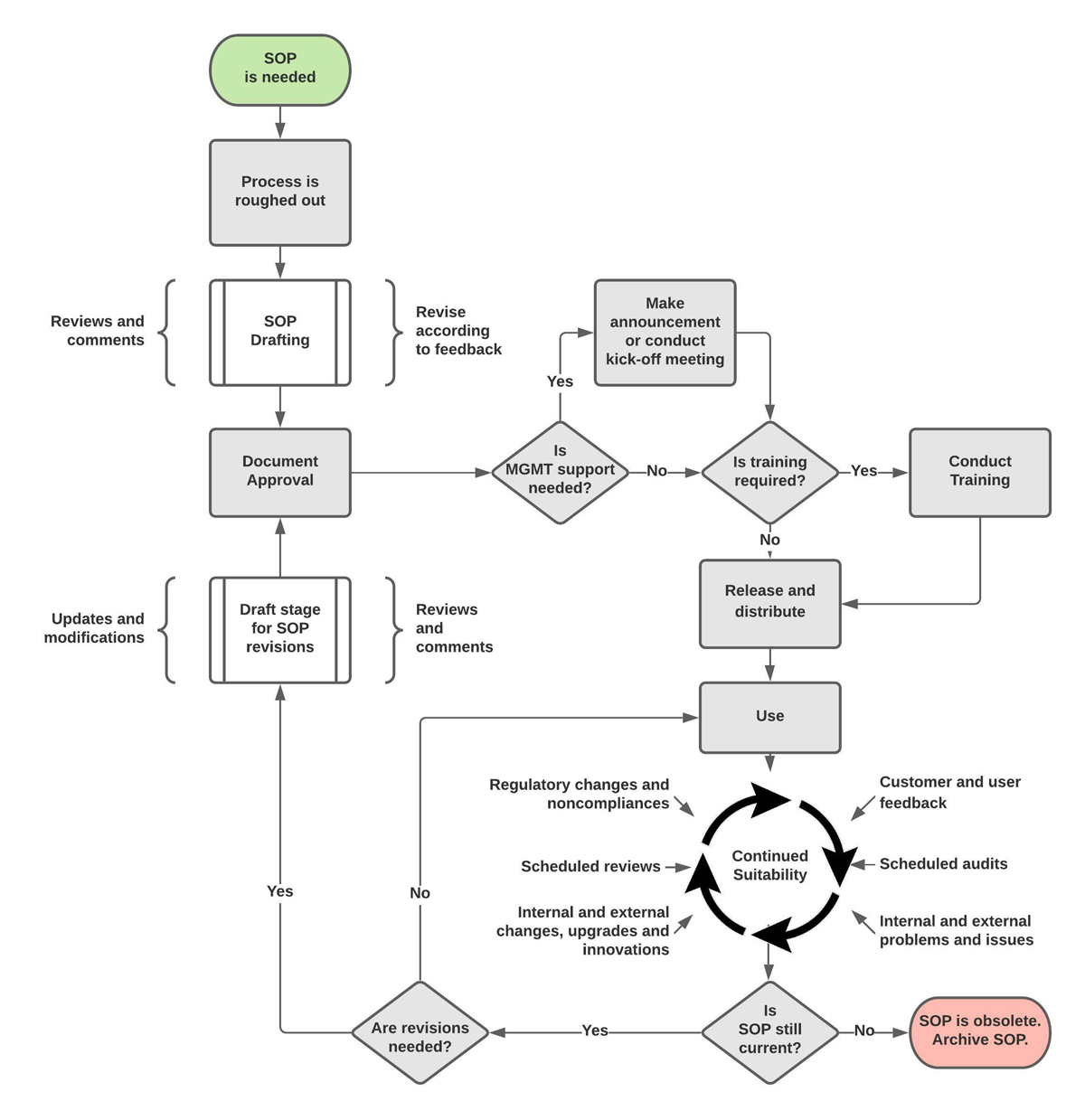

A key aspect of effective SOPs is that they are living documents. They need to provide sufficient detail while also adapting to changing circumstances in the work environment — an outdated SOP is no longer a safety asset but a liability. This requires effective SOP lifecycle management, where workers executing procedures have the ability to easily log feedback and assigned employees review procedures on a regular basis.

- This diagram shows a typical SOP lifecycle management process (adapted from Marcia Weeden/ASQ).

As SOPs are revised, documentation needs to be updated, versions need to be controlled and updated procedures need to be communicated. Traditionally this has meant a nightmare of tracking down physical copies and replacing relevant sections with these updated procedures.

Thankfully, digitization of SOPs greatly reduces this management burden and encourages more frequent updates and amendments.

In this post we won’t focus too much on SOP lifecycle management, but rather on the innovations RealWear and JourneyApps bring to the table when it comes to SOP execution.

3 SOP Innovations Made Possible By RealWear & JourneyApps

1. Voice Decreases Time To Complete SOPs

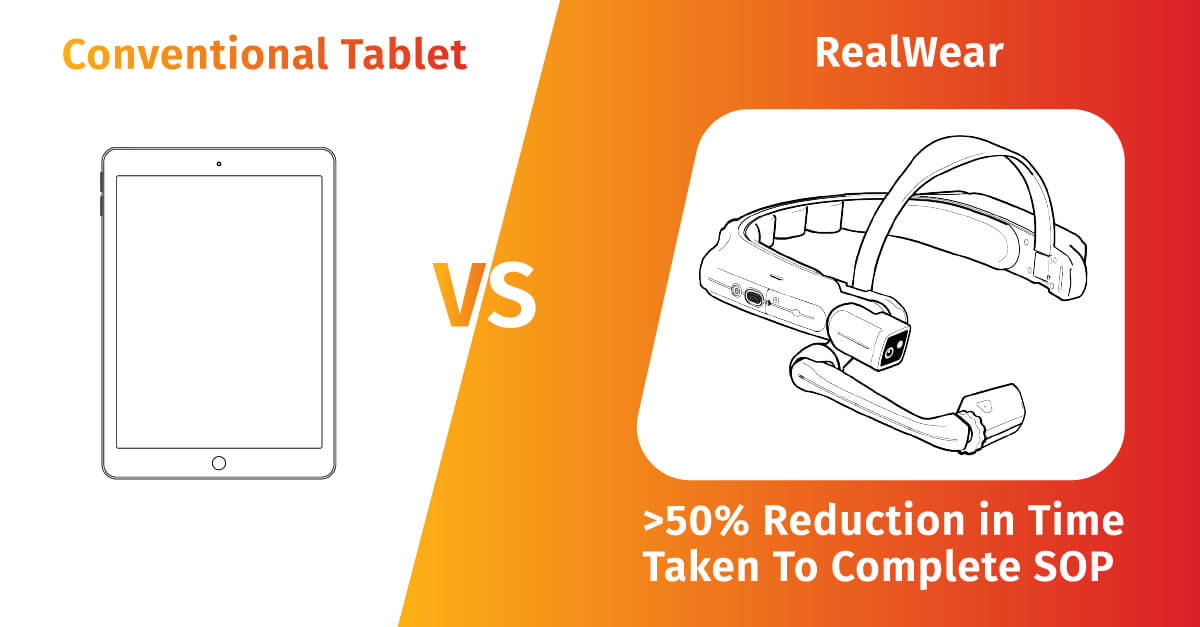

A major ROI driver for using RealWear for SOP execution is the amount of time saved through hands-free voice-driven app navigation. In fact, a Fortune 500 JourneyApps customer converted an existing app to run on RealWear’s HMT and reported an over 50% time saving when conducting the same process on RealWear compared to on a conventional tablet.

Thinking of how voice commands are used in more familiar settings makes it easy to understand why: imagine a home cook who realizes they need to add a specific ingredient to their shopping list for their next store run. The time it takes to stop what they’re doing, pick up their phone, navigate to the right app and type out H-O-T S-A-U-C-E is much longer than simply saying: “Hey Siri, add hot sauce to my shopping list.”

For SOPs, this information would include sensor or gauge readings, measurements, parts checked, checklists completed, photos and more. All of this data can be captured through voice.

2. Workers to Stay In Flow With Hands-Free Access To Documentation

Another common requirement for SOPs and maintenance processes is viewing reference documentation related to the process being executed. This can include schematic diagrams, hazard identification charts, or reference images.

RealWear allows users to view these documents hands-free, meaning that instead of having to stop what they’re doing and remove their gloves to pick up a paper sheet or tablet, employees are able to view critical information while staying in flow.

This results in users using reference documentation more frequently, leading to more accurate execution of procedure steps.

- The difference between using paper or tablets to view documentation versus using RealWear’s HMT is the difference between interrupting versus staying in flow.

3. Integration With Modern Industrial Hardware

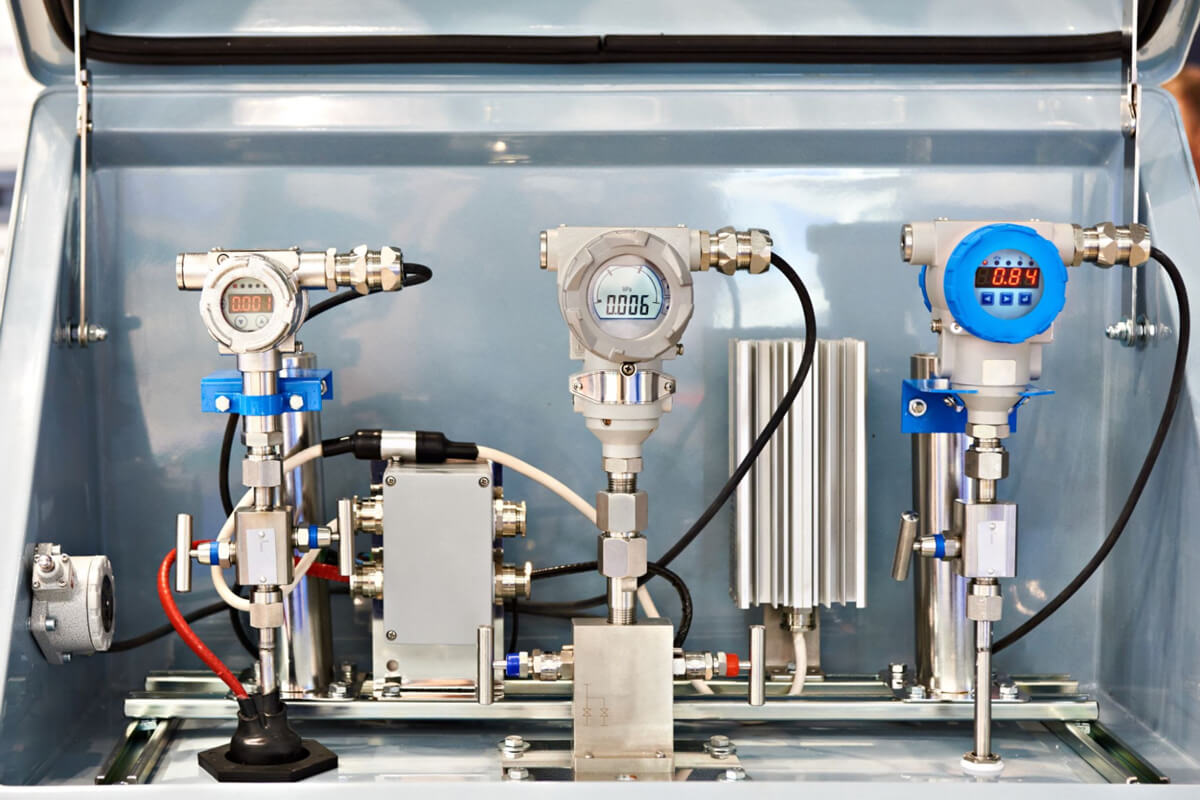

Many industrial facilities have embraced modern industrial equipment and technologies like BLE or WiFi-enabled sensors and protocols such as MQTT. The problem is that many SOP processes do not benefit from these improvements because they still require workers to manually read sensor data and input it on their paper forms or tablets.

- As an example, the JourneyApps hardware engine makes it simple to receive equipment metrics directly from pressure sensors and transmitters.

The JourneyApps hardware engine allows for SOPs to integrate directly with industrial hardware so that readings can be taken directly from sensors, without risking human error that could jeopardize data integrity. In fact, the ability of JourneyApps to interface with just about any hardware or software on site is a major reason why we decided to partner with RealWear.

BONUS: Combine SOP Execution With 3D Animations

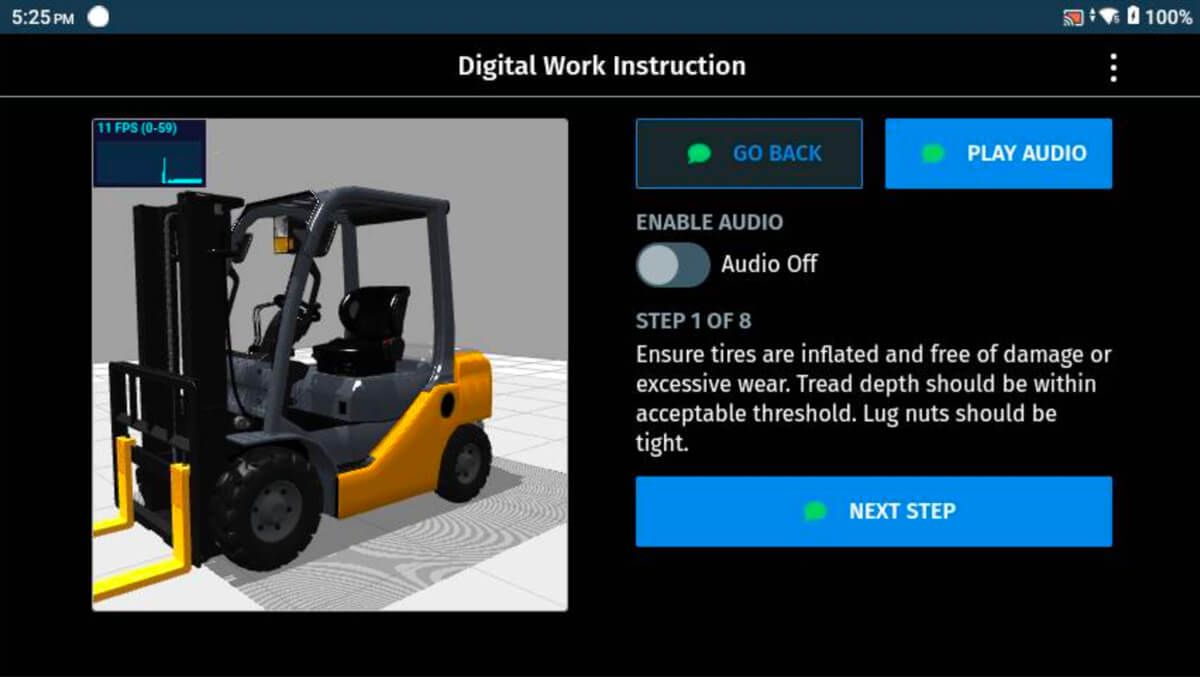

We’re seeing more and more customers looking to leverage 3D animations to guide technicians and engineers through processes – think of this as the logical progression for processes where it makes sense to implement a remote expert solution.

The idea is simple: along with an instruction for a specific step in an SOP, a 3D animation is shown demonstrating what needs to be done. In addition to the animation, the instruction itself is often read aloud through the HMT device. Users can replay the animation and progress step by step with voice commands.

- An example of 3D animations shown alongside work instruction steps.

Conclusion

There’s never been a better time to digitize outdated SOPs: the combined technology of RealWear and JourneyApps makes extended reality an accessible avenue for operational improvements that carry a strong business case.

JourneyApps provides a rapid way to build custom apps for RealWear® HMT, mobile and desktop. Auto voice commands are simple to set up and manage, we provide offline support out of the box, and deploying apps happens with a single click. Comes with prebuilt ERP integrations. If you are interested, please contact us to schedule a demo. You can also visit our RealWear page to learn more and subscribe for notifications about new blog posts.